- 1. Introduction

- 2. What Are Thermal Tattoo Printers?

- 3. Are Thermal Tattoo Printers Safe?

- 4. The Science Behind Thermal Tattoo Printers

- 5. How to Safely Use Thermal Tattoo Printers?

- 6. Common Issues and Their Solutions

1. Introduction

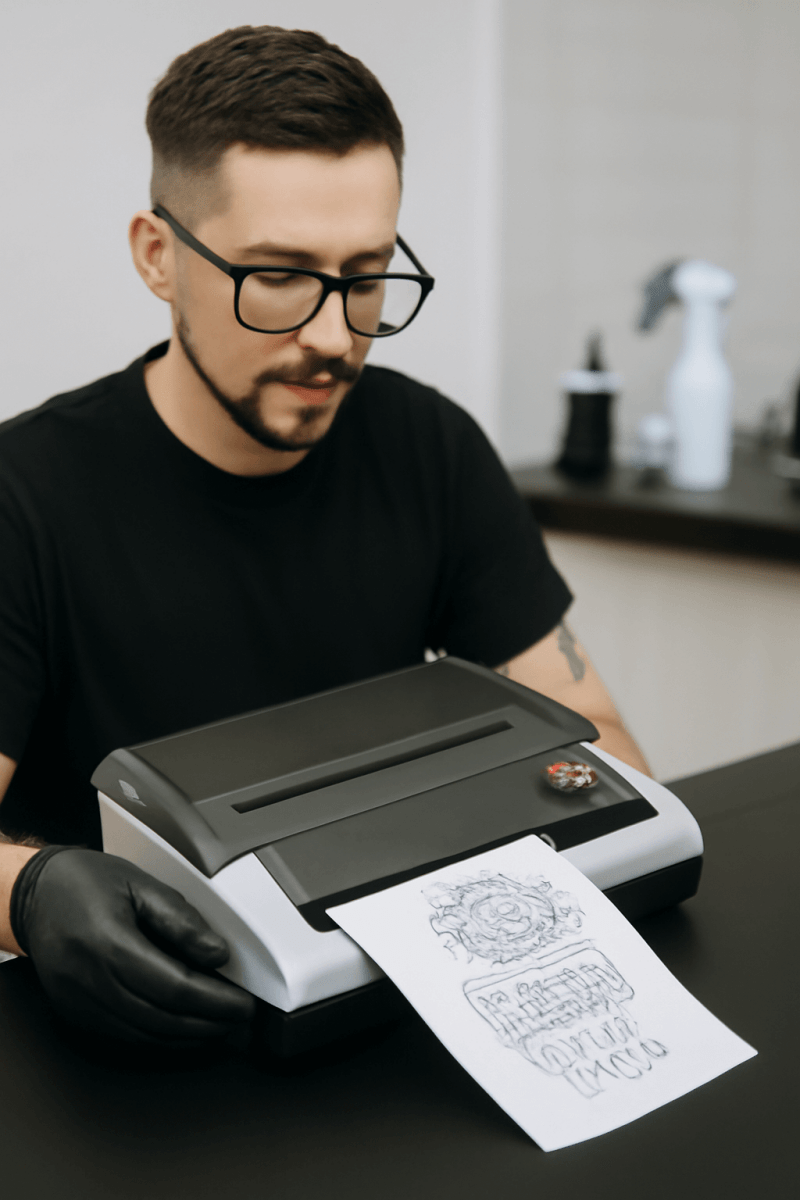

Thermal tattoo printers have become increasingly popular in the tattooing industry, providing tattoo artists with a quick and efficient method for creating stencils. These printers eliminate the time-consuming task of manually tracing designs and offer a level of precision that traditional methods may lack. However, with any new technology, especially one that comes into direct contact with the skin, questions about its safety arise.

Understanding how thermal tattoo printers work, their safety, and best practices for using them is crucial for tattoo artists and clients alike. This guide will explore the safety of thermal tattoo printers, explaining the technology, addressing potential risks, and offering practical tips for safe operation to ensure a smooth and safe experience for everyone involved.

2. What Are Thermal Tattoo Printers?

Thermal tattoo printers are devices designed to transfer stencils onto tattoo paper using heat. Unlike traditional methods, which rely on manual tracing, thermal tattoo printers utilize heat to directly transfer ink from a thermal transfer paper onto the stencil paper, ensuring a sharp, clear design. This process eliminates the risk of human error and smudging, making it ideal for both detailed and large designs.

How Do Thermal Tattoo Printers Work?

These printers use a thermal head that generates heat, which is applied to the special thermal transfer paper. The heat activates the ink on the paper, transferring it to the surface below. This process is similar to thermal fax printing but with higher precision and optimized for the tattooing process.

One of the key advantages of thermal tattoo printers is the ability to quickly create accurate stencils. With just a few settings adjustments, the printer can handle designs of varying complexity, saving time and improving workflow. The precision of the thermal printer ensures that every line of the stencil is sharp and ready for application onto the skin.

Why Use Thermal Tattoo Printers?

Thermal tattoo printers offer a range of benefits for tattoo artists. They provide consistent, clear stencils in a fraction of the time it would take to manually trace designs. They are especially helpful when working with intricate designs or larger tattoos that would otherwise require significant effort. Additionally, the heat application prevents ink smudging, ensuring that the stencil remains intact throughout the tattooing process.

The automated process also reduces the risk of mistakes during stencil application, providing both artists and clients with a smoother experience. The precision and speed make these printers an essential tool in modern tattoo studios.

3. Are Thermal Tattoo Printers Safe?

When used properly, thermal tattoo printers are safe for both tattoo artists and clients. However, as with any equipment that involves heat and ink, there are some safety considerations to keep in mind. Let’s address the most common concerns.

Potential Risks and Concerns

1. Skin Sensitivity

The heat from a thermal tattoo printer is typically controlled and should never directly touch the skin. However, in the case of equipment malfunctions or improper use, there is a slight risk of burns or irritation. Such occurrences are rare and usually happen due to incorrect printer settings or lack of maintenance.

2. Ink and Material Safety

The safety of thermal tattoo printers heavily relies on the inks and materials used. Some cheaper, non-certified inks may contain harmful chemicals that can irritate the skin. Always ensure that you’re using tattoo-specific transfer paper and inks, which are designed for skin safety. These materials are made with non-toxic, skin-friendly ingredients to minimize the risk of allergic reactions.

3. Electrical Hazards

As with any electrical device, thermal tattoo printers can pose an electrical hazard if not handled correctly. Regular inspection and maintenance, including checking power cords and ensuring the printer is free from damage, are essential for safe operation. Keeping the printer in a dry, clean environment will also reduce the risk of electrical malfunctions.

Most thermal tattoo printers are manufactured to meet international safety standards, such as CE and FCC certifications. These standards ensure that the printer is designed and tested to meet safety, health, and environmental requirements, providing a layer of assurance for both tattoo artists and clients. Following the manufacturer’s guidelines for maintenance, operation, and ink usage will further ensure safe use.

4. The Science Behind Thermal Tattoo Printers

Thermal tattoo printers use a thermal transfer process, which involves controlled heat to transfer ink onto stencil paper. Here's a deeper look into the components and science behind this technology:

Thermal Transfer Process

At the heart of a thermal tattoo printer is the thermal head, which uses small heating elements to apply heat to the transfer paper. The heat activates the ink on the paper, which then transfers the design onto the stencil paper below. The heat applied is minimal, just enough to activate the ink without damaging the paper or creating excess heat.

Components of a Thermal Tattoo Printer

1. Thermal Head

The thermal head is the most crucial part of the printer. It controls the heat and ensures that the correct temperature is applied to the transfer paper to produce an accurate stencil. Proper maintenance of the thermal head is essential to avoid uneven heating, which could affect the quality of the stencil.

2. Thermal Transfer Paper

This paper is specially designed for thermal printers. It contains a layer of ink that is activated by heat. The quality of the thermal transfer paper plays a significant role in how well the ink transfers to the stencil paper, and using high-quality paper is essential for clear, crisp designs.

3. Ink

Ink is typically embedded in the thermal transfer paper. It’s essential to use tattoo-specific inks that are non-toxic and safe for skin contact. These inks are formulated to ensure they last during the tattooing process and don’t cause irritation.

Heat Control and Safety

The heat applied by the printer is carefully controlled to avoid overheating. The printer’s internal system ensures the temperature is kept within safe limits, allowing the heat to be concentrated on the transfer paper, not on the skin. Overheating can lead to paper burns or damage to the stencil, so it is crucial to calibrate the printer correctly and ensure it is in good working condition.

5. How to Safely Use Thermal Tattoo Printers?

Using thermal tattoo printers safely involves a few key practices. These guidelines will help you get the most out of your printer while ensuring that both you and your clients are safe:

1. Use the Correct Materials

o Always use tattoo-specific transfer paper and ink to avoid skin irritation and ensure accurate stencils.

2. Calibrate Printer Settings

o Adjust the temperature settings according to the paper and design requirements. Avoid setting the printer to excessive heat levels, as this can damage the paper or cause poor transfers.

3. Maintain Your Printer Regularly

o Keep the thermal head and other components clean to ensure even heat distribution. Regular maintenance prevents overheating and maintains print quality.

4. Follow Hygiene Protocols

o Before using the printer, ensure your hands are clean, and the workspace is sanitized to prevent contamination of the stencils.

5. Avoid Direct Contact with Skin

o The printer’s thermal head should not touch the skin. Always ensure the printer is only used for transferring the design onto the stencil paper.

6. Common Issues and Their Solutions

Although thermal tattoo printers are reliable, some common issues may arise. Here are some typical problems and their solutions:

1. Faint or Unclear Stencils

o Solution: Ensure the correct temperature settings are being used. Replace the transfer paper if it’s worn out.

2. Wrinkled Transfer Paper

o Solution: Load the paper properly and ensure the temperature settings aren’t too high. Use wrinkle-resistant paper to prevent this issue.

3. Paper Jams

o Solution: Regularly clean the paper feed mechanism to prevent ink buildup that can cause jams.

Thermal tattoo printers are an invaluable tool for modern tattoo artists, offering speed, precision, and reliability. When used properly, they provide an efficient way to create high-quality stencils that are easy to apply and deliver great results. By following proper maintenance and safety guidelines, and ensuring the use of safe materials, thermal tattoo printers can be a safe addition to any tattoo studio.

With the right care, these printers can help you produce stunning tattoos with ease, while providing a smooth and safe experience for both you and your clients.

Share:

Thermal Tattoo Printer vs. Inkjet Tattoo Printer

Can Thermal Tattoo Printers Print on Skin?